The process of planning the OS&E orders with China does not seem difficult on paper. You receive a quote, agree on quantities, and wait several weeks to receive them. In the real projects, it is rarely so. Failure to schedule OS&E lead time in China appropriately will result in small delays soon turning into missed opening dates, hasty air freight, and sundry cost hikes.

You can be in control when you have learned about the cycle of production and the cycle of holidays and peak seasons in China. You learn not to be reactive to delays and begin planning for the delays. This guide will take you through the steps to follow when planning OS&E orders in a realistic way in the face of common risk areas and how to do it practically. planning OS&E orders with confidence.

What Is the Typical OS&E Lead Time in China?

In the majority of the projects, the OS&E lead time in China is between 8 and 20 weeks between confirmation of an order and delivery. Certain simple products will be quicker moving as compared to specialized or large-volume products.

It should not be relying on one number. The lead time is determined based on product type, level of customization, factory activity, holidays and shipping mode. The more complicated your order is, the more time you would need to plan.

Understanding OS&E Production Cycles in China

You cannot plan timelines before you understand the real workings of OS&E production.

How OS&E is Manufactured in China

The majority of the OS&E orders have a systematic flow:

1. Material Sourcing (2-3 weeks):

Factories work according to the model of just-in-time. They do not hold on to any particular grade of stainless steel, custom cloths, or branded parts until your deposit is cleared.

2. Golden Sample and Prototyping (2-4 weeks)

The stage determines the final product. Custom branding, Pantone colors or electrical certifications have to be physically approved. Delays in this case have consequences on the things that come after.

3. Mass Production (4-12 weeks)

- Soft goods: 4-6 weeks.

- Lighting and electronics: 6-8 weeks (testing must be done 1).

- Custom furniture: 8-12 weeks (wood drying and finish drying).

4. Quality Control and Technical Checks (1–2 weeks)

Burn-in Testing of Electronic and Moisture Checking of Wood Products.

5. Export Preparation (1 week)

Products are made palletized, sealed, marked, and ready to be loaded into containers.

Every step is based on the former. A slack time of one of the stages affects the whole timeline.

Standard Production Time by OS&E Category

The various OS&E products have varied speeds, even in the same project.

Category | Typical Lead Time | Common Delay Reason |

Furniture & case goods | 6-10 weeks | Wood approvals, wood curing, wood finish approvals. |

Lighting & electrical | 4-8 weeks | Certifications, safety testing. |

Bathroom accessories | 3-6 weeks | Plating or finish changes |

Soft goods | 4-7 weeks | Sourcing of fabrics, color matching. |

Such schedules are based on a smooth approval and regular factory workload. They are in a hurry extending due to busy seasons or changes made late.

Why OS&E Lead Time in China Is Often Longer Than Quoted

Most purchasers are appalled when actual schedules of work surpass what the suppliers promised. This normally occurs due to the fact that lead times quoted are based on perfect conditions. Factories in real projects have to deal with numerous orders, shifting priorities and external disruptions simultaneously.

Factory Capacity vs Reality

To have production lines full, factories usually take on more orders than they can possibly produce at a given time. In the case of workload, long-term or recurring clients are often given first priority since factories are likely to avoid losing long-term relationships. Single or new projects are usually shifted back in the schedule.

In case there is a sudden increase in demand, you are likely to wait longer for the production to commence, even when the factory has accepted it.

Customization Always Adds Time

Bespoke sizes, finishes, materials, logos, or packaging require additional coordination and approvals. Factories might require new samples, new drawings or more testing prior to commencing production.

Even minor design modifications, a change of color or an update of hardware can stop the production and shift the schedules by days or weeks.

China Holidays That Impact OS&E Lead Time

The Chinese OS&E lead time is directly and quantifiably affected by Chinese holidays in China. Such dates influence the work with the factory, shipping time, and communication with the suppliers, and it is necessary to consider them when planning a project to avoid some unpredictable delays.

Chinese New Year: Biggest Delay Risk

The most important holiday by which OS&E production would be affected is Chinese New Year (CNY). The duration of closing of the factories is usually between two and four weeks depending on the region and the size of the factory.

- Pre-Holiday Rush: The factories usually work extra hard to complete pending orders in the weeks before CNY. Such hurry may lead to the problem of quality control and the risk of making mistakes.

- Post-Holiday Slowness: It is not that many workers resume immediately after CNY. Others might switch jobs thereby resulting in a shortage of staff. This will decrease the production and delay production by a few weeks.

- Material Delays: Suppliers also close down or slow down production, which may cause delays in the availability of raw material in orders made.

Other Major Holidays to Plan Around

CNY is the longest; however, there are a number of other holidays, which influence production:

- Golden Week (First Week of October): The offices of the government and the factories can be closed during some days. There is slower shipping and congestion of international freight.

- Labor Day (May 1-3): The Labor Day may have short factory closures and low staffing levels, leading to slow production.

- Mid-Autumn Festival (September/October): Factories hire fewer people, approvals, communications, and production are slowed down.

How Holidays Affect OS&E Orders

Holiday scheduling is important as it may have an impact on all order stages:

- Temporary Production Pauses: Factories can either shut down or replace workers with fewer workers.

- Late delivery of Raw Materials: The local suppliers and international suppliers usually delay during the holiday periods.

- Reduced Supplier Communication: The approval of samples, shop drawings and change requests is slow because of reduced staffing.

- Shipping Challenges: Ports could be overcrowded because shipments are made before and after the holidays.

Peak Seasons for OS&E Manufacturing in China

Peak season coincides with the world construction surgery and the exportation demand, which enhances rivalry in the production slots and shipping capacity.

When Peak Season Starts and Ends

- Time Of The Year: High season usually begins in late summer (August) and goes all the way through to early winter (December).

- Projects That Are Affected: Hotels, resorts and huge commercial developments usually order during these months, straining the factory capacity even more.

- Why This Period Is Busy: A lot of international work will have installations before the end of the year and therefore the factories have to speed up and handle numerous big projects at once.

Why Peak Season Causes Delays

- Factory Overload: There are a lot of full bookings of the production lines and other orders can get to wait for a slot.

- Port Congestion: There is a congestion of export ports where various shipments of goods vie against each other with restricted containers.

- Inspection Bottlenecks: Quality checks can be slowed down because of higher volume, which slows down the approval of the finished goods.

Raw Materials: Raw material delays are caused by high demand, which increases the total lead time.

High-Risk Months for OS&E Orders

- August to November: Orders made in these months are at the greatest risk of delays because of the confluence of the holiday seasons, peak production times and shipping congestion.

- Planning Tip: Have an additional buffer time when your project is in this range in case of the project and delivery in time, as well as expedited shipping opportunities, which are costly and hasty.

Realistic OS&E Lead Time Timeline (End to End)

The planning of OS&E orders must be done based on the whole timeline and not only factory production. Delays normally occur in between the stages, particularly where approvals or logistics are delayed.

Step-by-Step OS&E Order Timeline

1. Supplier Confirmation and Deposit

This is a step that will book you a production slot. Factories do not customarily obtain materials or arrange your order until the deposit is cleared.

2. Shop Drawings and Samples

This level provides accuracy of products. Any postponements in the approvals in this case are pushing all the down-the-line activities, such as production and shipping.

3. Mass Production

Factories start being manufactured once approved. The pace of production is determined by the workload at the factory, level of customization, and availability of materials.

4. Quality Inspection

Specifications, finishes, and functionality are checked during inspection and then packed. It is always tempting to omit or cut this step which later results in expensive rework.

5. Packing and Export Preparation

OS&Es are safeguarded by packing properly for long-distance transport. It is also at this stage that export documentation is prepared.

6. Shipping and Customs Clearance

The end-to-end timeline is completed by transit time and customs processing. This phase may take in excess of the anticipated time in peak seasons.

There must be approvals and written confirmations and follow-ups in every stage in order to remain on schedule.

Typical Time Ranges at Each Stage

Stage | Estimated Time |

Confirmation & samples | 2-4 weeks |

Production | 4-12 weeks |

Inspection & packing | 1-2 weeks |

Shipping & customs | 3-6 weeks |

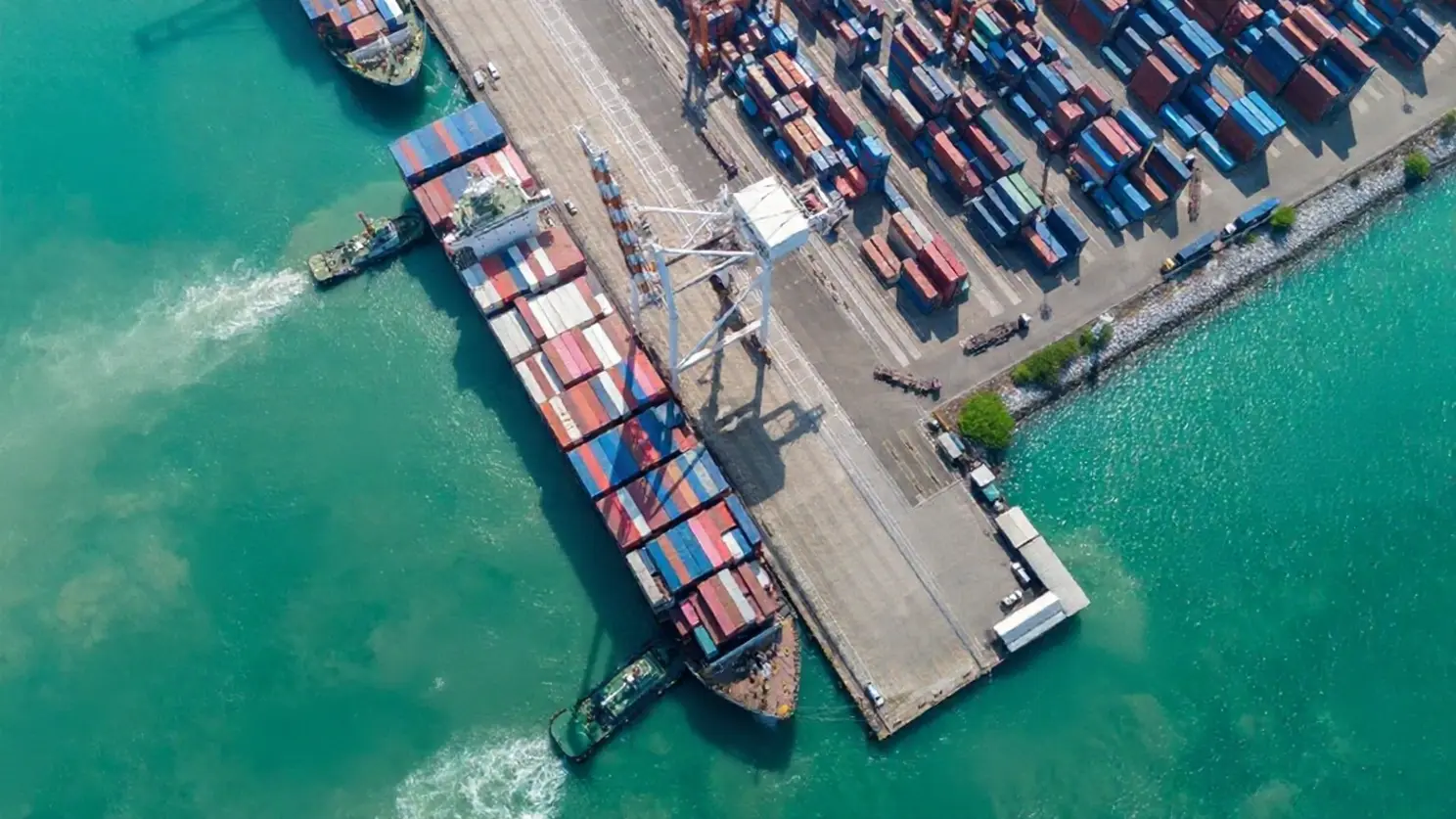

Shipping Time: The Hidden Factor in OS&E Lead Time China

Being frank, when looking at a project calendar, you may find yourself looking at the time on the water and thinking that you are good to go. However, there is so much more than the boat ride to shipping in 2026. Unless you take the "invisible" days into consideration, you may end up having an otherwise lovely hotel that is all ready to open—but not a towel or a piece of furniture to furnish it!

Sea Freight vs. Air Freight: Which One Is Your Best Friend?

There are two primary methods of transporting your goods and the decision is usually whether to spend your money or your heartbeat (stress levels!).

Sea Freight (The Reliable Workhorse): This will be that of you. It maintains a predictable and manageable cost. Ocean freight remains 10-15 times lower than air in 2026.

- The Reality Check: You must be patient. When you are shipping to the West Coast of the US, you need to estimate 25-30 days. Coming to Europe or the East Coast, it will be at least 50 days on board, since the ships are now going round Africa the long way.

Air Freight (The Emergency Brake): This is your break-glass-in-case-of-emergency choice. It is extremely quick (3-7 days), yet it will consume your budget.

Our Advice: Air freight. We recommend air freight only for those minor items you've forgotten or that have been delayed—such as custom door handles or that particular light bulb—to be sure that you are on time on your opening day.

Navigating the "Triple Delay" (Don't Let These Surprise You!)

You are not clear yet even when your goods have left the factory. There are three things we two need to be vigilant about:

- Vessel Rollovers: It is like arriving at an airport with a ticket to fly and being informed that the plane is full. That's a "rollover." In 2026, carriers are very often pushing containers onto the ship of the following week. This can just as easily add 7-14 days of time that you need to wait before you even start the journey.

- The Dwell Time Trap: The ship has arrived at the port, however, is that a sign that your goods are ready? Your container can wait 5-9 days in the dock waiting for a crane or a truck. It is as though one were awaiting baggage handling, only that it is now two weeks long!

- Customs "Intensive" Exams: It is the linens, towels, and wooden furniture that the customs officers are being extra-vigilant with in 2026. When your shipment is selected to be examined intensively, it may take 10-14 days to be inspected.

My Secret Tip for You: When you make an appointment with a date on your calendar to have it installed, you should leave yourself a 3-week "buffer" after the approximate date when the ship is expected to arrive. In case the goods come in time, you are a hero. And should they be held at the port, you are all on time.

Common Mistakes That Cause OS&E Delays

OS&E delays often occur because of preventable planning mistakes and not factory breakdowns.

1. Trusting "Estimated" Dates

The projected estimation date of a factory is an ideal scenario. Thou must never fail to put a 20% saving margin on thy schedule.

2. Skipping Third-Party Inspections

It is much more expensive to find mistakes once it has arrived than to correct them at the factory. Quality and timelines are guarded by early inspections.

3. Ignoring Packaging Specifications

OS&E items tend to have delicate parts. Normal packaging in a factory can hardly be delivered to the ocean without being damaged during the ocean transportation or inland transportation.

4. Late Payment of Deposits

Clearance of payments takes the place of verbal confirmation as production slots. Any delays in payment, even in the short term, can cause a delay in production that can take weeks.

These errors are avoided to safeguard the timelines and budgets of a project.

How to Plan Your OS&E Orders from China Properly

Smart planning does not only mean creating a list; it means lessening your stress, safeguarding your budget and not finding yourself having a quiet opening due to the fact that your goods have not arrived at the docks yet. The following is how you may assume control of the process.

Build a "Strategic Buffer" Into Every Order

The estimated date of a factory is often made with regard to an ideal world in which the machine can never malfunction, and the material will always arrive immediately.

- The 20% Rule: There is a rule of thumb that any production quote should be increased by 20%. When they say 10 weeks, then plan to have that of 12.

- The "Golden Sample" Buffer: Please remember to include the time that it takes to deliver a sample to you and how long it takes you to accept it. Such a back-and-forth can add 3 weeks prior to the actual mass production with ease.

Align Your Orders with Construction Milestones

Among the greatest errors you can make is to take all your OS&E with you the moment you are ready. And when the building is not prepared to receive it, you get stuck with a headache.

Sequence Matters: You do not need your teaspoons together with your mattresses. Your deliveries should be planned by the sequence of installations:

- Phase 1: Massive goods (Mattresses, safes, minibars).

- Phase 2: Room furnishings (Linens, towels, and kettles).

- Phase 3: High value/Perishable (Glassware, amenities, electronics).

Avoid the "Storage Trap": Delivering too soon causes congestion of the site, hand-handing, and above all, accidental destruction at the hands of the construction workers who are still at work on the finishings.

Work With Experienced OS&E Professionals

You don't have to do this alone. Dealing with a committed sourcing counterpart in China makes the difference between the wishful thinking of the best-case scenario and the reality of the facts.

- Real-Time Accountability: A professional group will have boots on the ground to check that the factory is at its stated stage.

- Problem Solving: When a material shortage occurs, you can get another supplier or bargain to get a priority slot in case a material shortage occurs that a single buyer may not have.

How Deper Ensures Your Project Stays on Track

At Deper, we do not simply place an order to be filled; we deal with risks. We provide:

- Real-time Monitoring of the Factory: The boots on the ground are here to ensure that mass production is the same as the approved sample.

- Logistics Optimization: We combine several categories of OS&E into FCL containers to decrease the costs and the time of the customs.

2026 Calendar Guarding: We will beat your business ahead so that your orders will not be caught in the CNY and Golden Week dead zones.

OS&E Lead Time China: Best-Practice Timeline Example

Assuming you have a typical hotel project, you need to have your OS&E orders in five to six months prior to your date of the Soft Opening. Here is what 24 weeks of this is going to look like to you:

- Weeks 1-4: Selection, offer and deposit payments.

- Weeks 5-8: Prototyping and "Golden Sample" approvals.

- Weeks 9-16: Mass production (and an intermediate inspection!).

- Week 17: Final Quality Control (QC) and loading of the containers.

- Weeks 18-22: Cargo transportation and clearance by the ocean.

- Weeks 23-24: In-sourcing and white glove installation.

My Personal Advice: Take into consideration your 6-month window as an insurance policy. It enables you to absorb the little hiccups, such as an ill week at the port or a small design change, without ever, not once, having to incur the cost of costly last-minute air freight.

Final Checklist to Avoid OS&E Delays

- Plan the Chinese holiday schedule in advance.

- Accept samples within the shortest duration possible.

- Establish a schedule of production in writing.

- Arrange scheduled inspections.

- Select shipping processes wisely.

- Introduction of buffer time at each stage.

Conclusion

The planning of OS&E lead time in China should be realistic based on expectations and scheduled ahead. Once you get a feel for production cycles, holidays, and peak seasons, you will not get caught up by last-minute surprises and will safeguard your project timeline.

We will assist you in making smarter plans at Deper through sourcing, timelines and quality management. Our attention is paid to achievable timelines, effective communication, and minimizing risks.

To evade OS&E delays and to keep your project on time, then refer to our team and have us on board to take care of your next project.

FAQs

1. What affects OS&E lead time in China the most?

The most significant have been factory workload, level of customization, holidays, and shipping method.

2. How early should you place OS&E orders?

Large projects should have orders placed at least 4-6 months before installation.

3. Does Chinese New Year affect all OS&E products?

Yes. Practically every factory halts or slows down the production at this season.

4. Can inspections reduce OS&E delays?

Yes. The issues are detected during inspections and avoided during reworking after delivery.

5. Is faster shipping a good solution for delays?

Quick shipping is useful in times of emergency, whereas early planning of works is more efficient and cheaper.